Objective

Design and build a device that can launch a small projectile (a standard size marshmallow) at a target with accuracy and precision.

Requirements

1. The launcher must fit inside a 2 ft. cube. This measurement will be taken when the launcher is completely assembled and ready to fire.

2. The launcher can be manually armed or loaded, but the firing or launch event must be done with a remotely activated firing mechanism. The firing mechanism must be operated at least one foot away from the launcher and it must be operated from either side of the launcher rather than in front of or directly behind it. The firing mechanism must be contained and cannot become a projectile.

3. No combustion or pneumatic devices that explode or store pressurized gas over 5 PSI are allowed. Nerf-style launchers using a spring to generate a puff of air are allowed. Homemade pressure vessels are NOT permitted.

4. Your launcher must be safe to operate. Any project deemed unsafe by an instructor will not be allowed to participate in the performance demonstration. Loading the device cannot place anyone in harm. If you have questions or concerns, TALK TO YOUR INSTRUCTOR BEFORE PROCEEDING!

5. You may not attach anything to the projectile or alter it in any way.

6. The launcher must be set up to launch as touching the starting line and be at floor level.

7. The entire launcher must be behind the launching line when loaded and ready to fire. No part of the launcher may end up further than 2 feet into the target zone after launching.

8. The launcher may not be fastened to the floor (taped, nailed, or glued). Friction holding techniques (Velcro, rubber pads, etc.) are permitted. You cannot use your body (foot, hand) to prevent movement or rotation during the launch.

9. The entire launcher system may not weigh more than 30 lbs.

10. The cost target for the launcher is $30.

11. Liquid counterweights may not be used.

12. Any voltages may not exceed 24 volts DC.

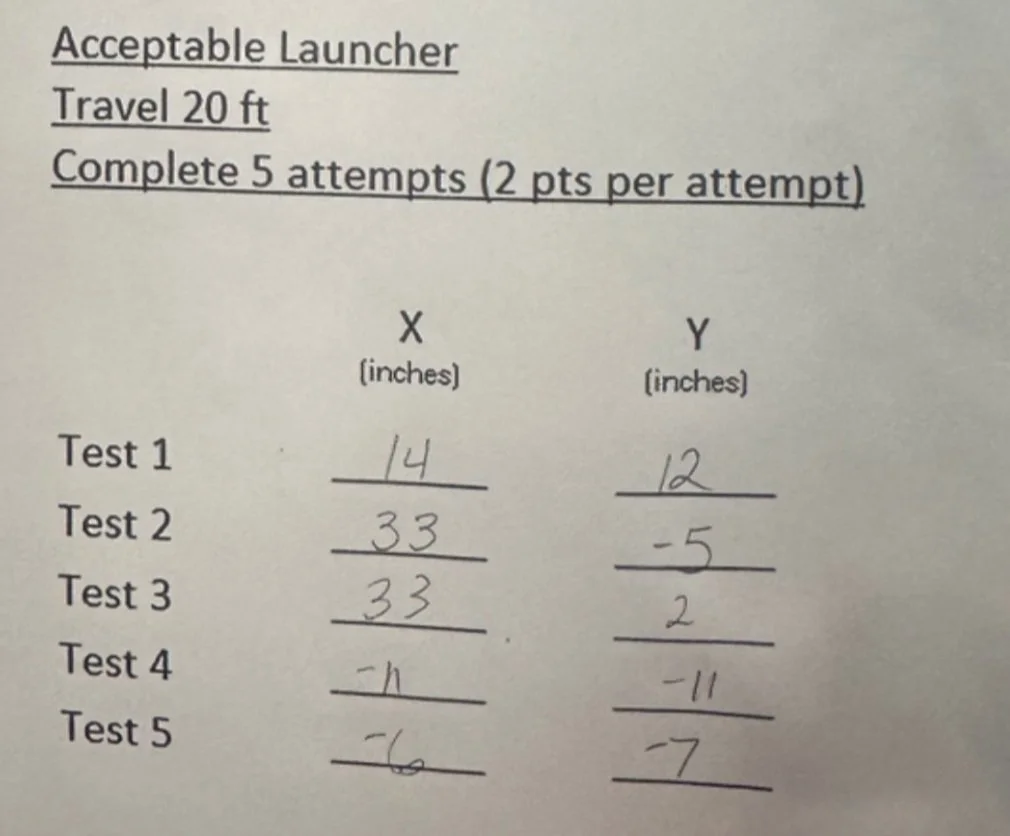

Results

The projectile was unable to reach the desired range and was unable to hit a target consistently. This was primarily due to the elastic type used.

The trigger functioned well after some modification. Due to time limitations, we could not reprint the trigger so added a shim on the cam to reduce the pressure required for forward and backward rotation.